Water treatment plant of Metsä Group’s Äänekoski bioproduct mill’s water treatment plant is now fully operational and running. Water treatment plant, demineralised water treatment plant and a condensate treatment system for the mill were delivered by Flootech, a leading provider of water treatment solutions. Flootech’s solutions produce high quality process water and demineralised water allowing a high operational reliability and production efficiency at the mill and power plant.

Flootech has a long co-operation relationship with Metsä Group, and this project is again an excellent example of a successful collaboration. Metsä Group’s Bioproduct mill is the largest wood-processing plant in the Northern Hemisphere producing pulp and other bioproducts. This modern mill represents the highest level of energy, material and environmental efficiency in the world. Key are leading solutions of the forest industry and Flootech’s expertise on water treatment technologies.

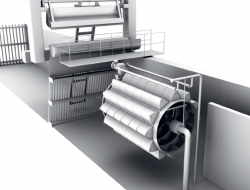

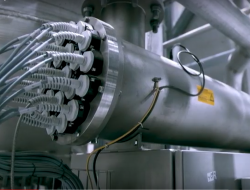

The water treatment plant includes solutions based on technologies developed by Flootech, such as FlooDaf® microflotation, FlooSand™ sand filtration and FlooIX™ ion-exchange technology. It has been designed to significantly increase energy efficiency through the recovery of waste heat from bioproduct manufacturing. Recycling of reject waters in water treatment plant is one part of solution to achieve very low specific water consumption at the bioproduct mill. The quality of the purified water is very high, and it can be used for demanding applications. Due to Flootech’s high technology solutions water, chemicals and electricity consumption of the plant are low.

The project was managed smoothly, finalized on time and without lost time accidents. Metsä Group’s project manager Johanna Harjula is satisfied with the results: “Water is an essential part of our bioproduct mill’s processes. Flootech’s expertise ensures, that our high requirements for water quality are fulfilled. Flootech’s solutions also ensure one of our key resource is treated in a most energy efficient way enabling excellent environmental performance in water management.”

See a video about the Äänekoski mill water treatment solutions