Boiler Feedwater

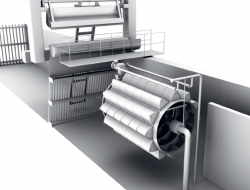

Our key processes for boiler feedwater production are FlooIX™ Ion Exchanger, FlooRO™ Reverse Osmosis and different types of filtration. Reverse osmosis is the finest filtration known. FlooRO™ Reverse Osmosis is used to produce water that meets the high water quality standards demanded by our clients.

The FlooMB™ Mixed Bed Ion Exchanger is a polishing unit used wherever the quality of the water produced from the main deionization section - both ion exchange or reverse osmosis type - is insufficient to meet the required standard. It is typically for use in a high-pressure boiler with a steam turbine, or in condensate polishing.

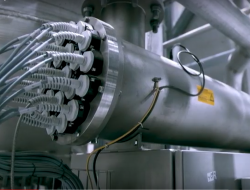

Condensate Polishing and Flue Gas Condensate

Boiler feedwater treatment is not adequate when small amounts of impurities can get into the condensate, causing corrosion problems. Polishing of the condensate is required in order to meet the quality needs of the high-pressure thermal cycles, and also to minimize consumption of make-up water. Flootech’s advanced solution for condensate polishing or flue gas condensate comprises cartridge filtration, FlooMB™ Mixed Bed Ion Exchanger and FlooRO™ Reverse Osmosis as well as different types of filtration.