Today, industrial plants are taking full responsibility for the way their process waters affect production and the environment. Fresh water taken from nature is cleaned, utilized and recycled carefully within the processes and, when returned to nature, that water must meet stringent standards. These targets can be achieved using FlooBed-based biological treatment solutions.

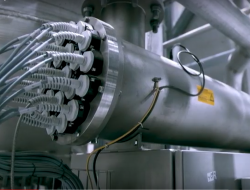

Flootech’s FlooBed bioreactor is a biological treatment process based on the moving bed bioreactor (MBBR) principle, where microorganisms are attached on carriers to break down organic compounds. The core component of the FlooBed process is the carrier element. Combined with optimized aeration and mixing, the microorganisms form a biofilm on the surface of the carriers and remove organic compounds. The carriers are suspended inside the reactor and are mixed efficiently through aeration.

The FlooBed process can be built to have one or several stages in series or in parallel. Excess sludge is removed from the carriers continuously by intensive mixing and abrasion. Microflotation is typically used for subsequent separation, or sedimentation, if applicable. Part of the sludge is recycled back to the FlooBed® system, and the rest is further dewatered.

Advantages of the FlooBed® MBBR

• A FlooBed® carrier is easy to operate because it is very tolerant to peaks of organic load and variations in flow rate. It tolerates temperature variations and toxins in the feed water.

• The reactor volume needed for a FlooBed® system is considerably smaller compared to activated sludge plants. Space requirement is typically 10-40% of conventional solutions.

The FlooBed® carrier has an open structure, which facilitates a high amount of biomass and improves mass transfer efficiency. The durable structure of the carriers makes them tolerant to mechanical abrasion, resulting in low maintenance costs.

The filling ratio of carriers can be adjusted on a caseby- case basis. In practice, this means the process is designed to be very flexible. Filling can be changed according to flow and load, and the FlooBed® carrier can be also built into an existing basin.

In fixed-film reactors, clogging caused by excess sludge can be a problem. The FlooBed® system minimizes this by creating turbulence that churns the water through the carriers, thus no backwashing is needed.

Design Parameters:

• Retention time typically from 1 to 4 hours.

• Organic load range 2–20 kg BOD/m3d.

• Biomass concentration in the reactor 6-12 kg/m3.

• On average 70–80% of microbes attach on the carriers.

• Low sludge circulation, 0–15% of the in-feed flow.

• Efficient aeration.

• Wide range of operating temperatures.

• Carrier filling ratio 20–60% of biomass and improves mass transfer efficiency.

The FlooBed® solution has been selected for several applications, such as effluents from process industries, landfill leachate and municipal wastewaters. In the pulp and paper industry, FlooBed® has been built into the mill area for pretreatment of existing activated sludge plants and for new mills with high requirements.