As environmental awareness has increased and regulatory requirements have proliferated, Flootech has become a leader in the development of equipment and technologies to meet the new demands.

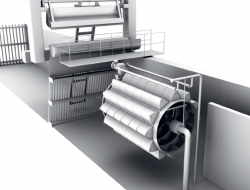

FlooDaf® Dissolved Air Flotation

Dissolved Air Flotation (also known as microflotation) is a well-known method of particle separation. Microbubbles are created by dissolving air into water under pressure. When the air-saturated pressurized water is released, microbubbles are formed. Chemical, physical and electrical forces cause suspended solids and colloids to attach to one another and to air bubbles. These particle flocs then float to the water’s surface and are scraped off. Coagulation and / or flocculation chemicals are used to enhance the process.

For coagulation and improved flocculation, chemical treatments are usually needed to maximize the efficiency of floc formation and separation.

Flootech offers circular and rectangular FlooDaf® microflotation units of several sizes and varieties to suit the particular needs of individual sites and to optimize the process.

FlooClari™ Clarifiers

Our Clarifier units are designed to provide the most economic solution for precipitation and clarification. The basic Clarifier design provides for coagulation, flocculation, solids recirculation, clarification and positive sludge removal in a single basin, eliminating the need for multiple tanks and associated piping. Flootech’s range of clarifier units, refined by years of application experience in the engineering and manufacturing industries, assure that a best fit solution can be found for any unique plant requirements.

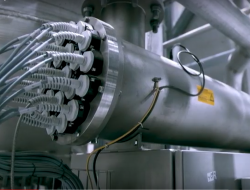

FlooSand™ Multimedia Sandfiltration

Flootech’s clarification process softens water, removes turbidity, algae, color, iron and metals. Ideal for removing suspended solids from raw water, if clarified water requires further polishing by filtering, residual solids are efficiently removed via granular media filtration systems, which use sand, anthracite and/or activated carbon. Solid particles are trapped in the media and, when exhausted, are flushed by backwashing with air and water.