Today’s requirements for decreased water consumption call for improved water management at mills. Flootech’s solutions born of significant pulp and paper industry experience respond solidly to that challenge.

Microflotation is a well-known method of particle separation; also called Dissolved Air Flotation (DAF), it has long been used in the pulp and paper industry for different applications, such as separation of ash fines, resin and other detrimental substances from processes.

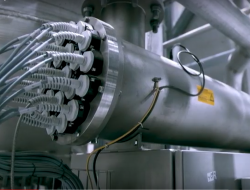

During microflotation, micro-sized bubbles are created by dissolving air into water under pressure. When the air-saturated, pressurized water is released, microbubbles are formed. Suspended solids and colloids attach to air bubbles and to one another due to chemical, physical and electrical forces. These particle flocs then float to the water surface and are scraped off. Coagulation and/or flocculation chemicals can be used to improve the separation.

Flootech focuses on cleaning and recycling process water in order to find economical, efficient and environmentally friendly solutions. Starting with an evaluation of the best technical solution for installation and start-up, we take full responsibility for supplying the complete process. Additionally, we continually seek to assure excellent levels of plant performance.

FlooDaf® Microflotation

FlooDaf's main features are its rectangular shape, automatic dispersion water and basin level control. As a result of this, FlooDaf Microflotation can have high hydraulic loading and a small footprint, while still maintaining good separation efficiency.

General Features

• Low space requirement.

• Excellent separation efficiency over large particle range.

• Excellent tolerance for hydraulic and solid variations.

• High solid concentration in the sludge.