WATER SPECIALISTS FOR THE MUNICIPAL WATER TREATMENT SECTOR

Almost always, the Municipal water treatment sector’s treatment of water is subject to exacting standards and regulations. Flootech can be relied upon to recommend the ideal processes, technologies and products for our clients to address their particular circumstances and meet their specific requirements.

As regulatory requirements have proliferated, Flootech has become a leader in the development of equipment and technologies to meet the new demands.

Clarifiers and Multimedia Sandfiltration

Our Clarifier units are designed to provide the most economic solution for precipitation and clarification. The basic Clarifier design provides for coagulation, flocculation, solids recirculation, clarification and positive sludge removal in a single basin, eliminating the need for multiple tanks and associated piping. Flootech’s range of clarifier units, refined by years of application experience in the engineering and manufacturing industries, assure that a best fit solution can be found for any unique plant requirements.

Flootech’s clarification process softens water, removes turbidity, algae, color, iron and metals. Ideal for removing suspended solids from raw water, if clarified water requires further polishing by filtering, residual solids are efficiently removed via granular media filtration systems, which use sand and anthracite. Solid particles are trapped in the media and, when exhausted, are flushed by backwashing with air and water.

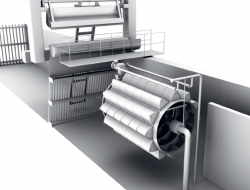

Dissolved Air Flotation

Residual oil and suspended solids are separated by dissolved air flotation (DAF) called FlooDaf® microflotation. During this process pressurized air is dissolved into recycled effluent water to generate micro bubbles. The pressure is then released into the feed flow. The bubbles produce agglomerates with smaller specific gravity than that of water by attaching themselves with suspended particles. These agglomerates rise through the liquid and the air-water-solid mixture is distributed uniformly across the flotation tank, thus forming a floating sludge layer that is removed by surface skimmers. Heavier solids settle to the bottom of the tank and can be discharged from there. Clear liquid supernatant on the sediment layer is withdrawn under a tank baffle and over the weir for reuse or for treatment by coagulation and flocculation.

For coagulation and improved flocculation, chemical treatments are usually needed to maximize the efficiency of floc formation and separation. Emulsions of oily materials can be broken by acidification, the addition of alum or iron salts (inorganic coagulants) and by using emulsion-breaking polymers.

Flootech offers circular and rectangular FlooDaf® microflotation units of several sizes and varieties to suit the particular needs of individual sites and to optimize the process.